Keeping Your Pizza Hot: Behind the Scenes of Our Thermal Delivery System

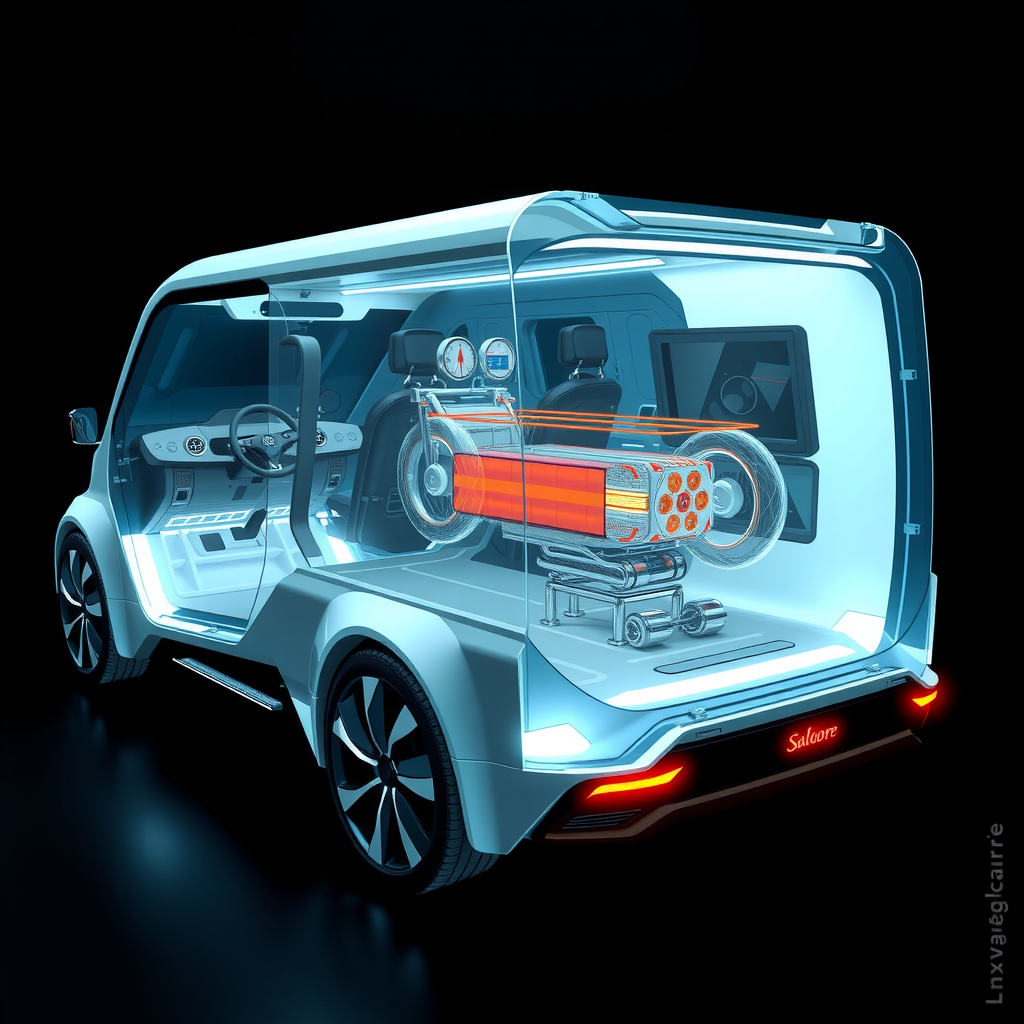

How Salvatore's innovative logistics strategies ensure your pizza arrives piping hot, even during harsh Canadian winters with temperatures dropping below -20°C.

When temperatures plummet to -20°C and below across Canada, most businesses face significant operational challenges. For a pizza delivery service like Salvatore, these extreme conditions present a unique problem: how do you ensure that a pizza baked at 450°C arrives at your customer's door still piping hot, with the cheese perfectly melted and the crust maintaining its ideal texture?

This isn't just about customer satisfaction—it's about delivering on our fundamental promise. A cold pizza isn't just disappointing; it's a completely different product. The mozzarella loses its stretch, the crust becomes chewy instead of crispy, and the carefully balanced flavors we've perfected in our kitchen are compromised. That's why we've invested heavily in developing what we believe is the most advanced thermal delivery system in the Canadian pizza industry.

Today, we're pulling back the curtain to show you exactly how we do it. From the moment your pizza comes out of our stone ovens to the second it reaches your hands, every step is carefully orchestrated to maintain optimal temperature and quality.

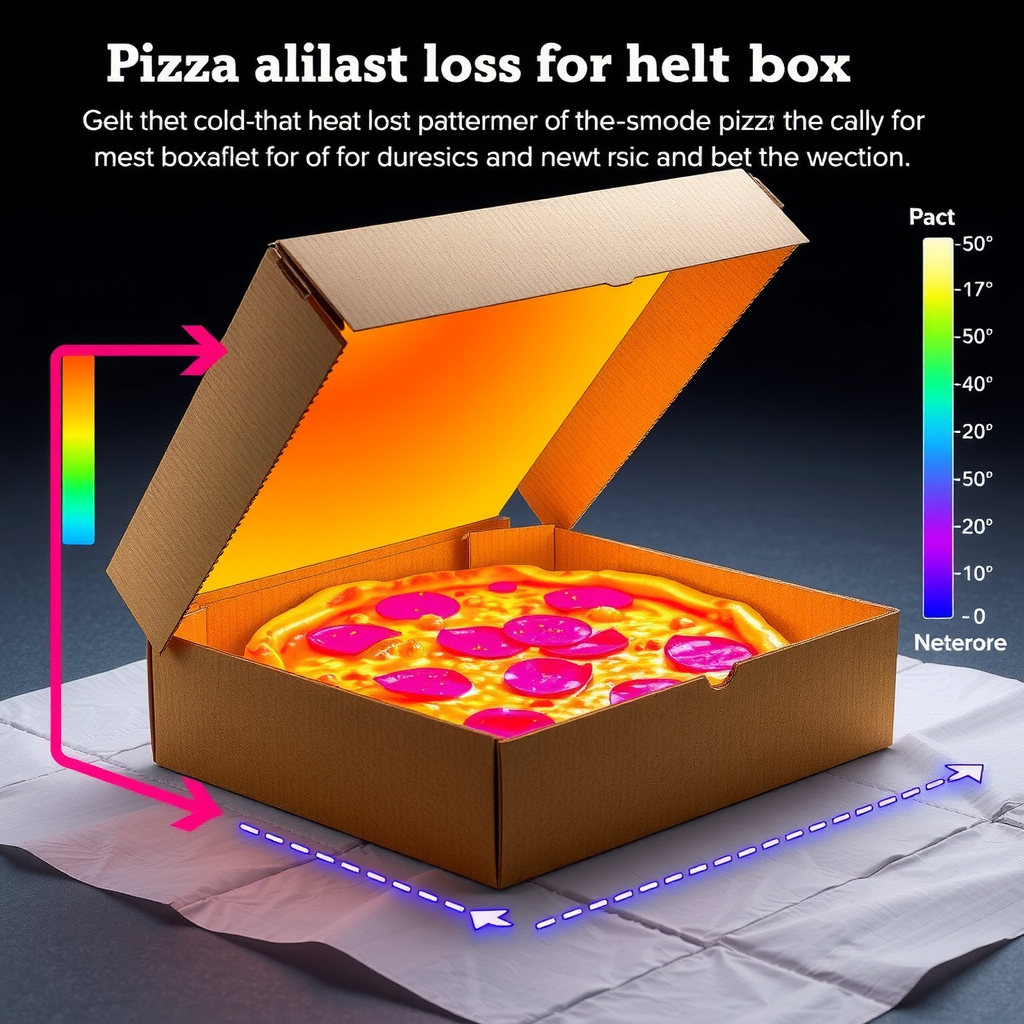

The Science of Heat Retention

Understanding heat loss is the first step in preventing it. When a pizza exits our oven at approximately 200°C internal temperature, it immediately begins losing heat through three primary mechanisms: conduction (direct contact with cooler surfaces), convection (heat transfer to surrounding air), and radiation (infrared heat emission). In extreme cold, these processes accelerate dramatically.

Our research showed that a standard pizza box in -20°C weather loses approximately 15°C every five minutes. This means a 30-minute delivery would result in a pizza arriving at barely 110°C—well below the 140°C threshold we consider acceptable for optimal taste and texture.

We needed a solution that could reduce this heat loss by at least 70%, giving us a comfortable margin even for longer deliveries in the most extreme conditions.

After extensive testing with thermal engineers from the University of Toronto, we developed a multi-layer insulation system that addresses all three heat loss mechanisms simultaneously. The result? Our pizzas now lose only 4-5°C every five minutes, even in the harshest conditions—a 67% improvement over standard delivery methods.

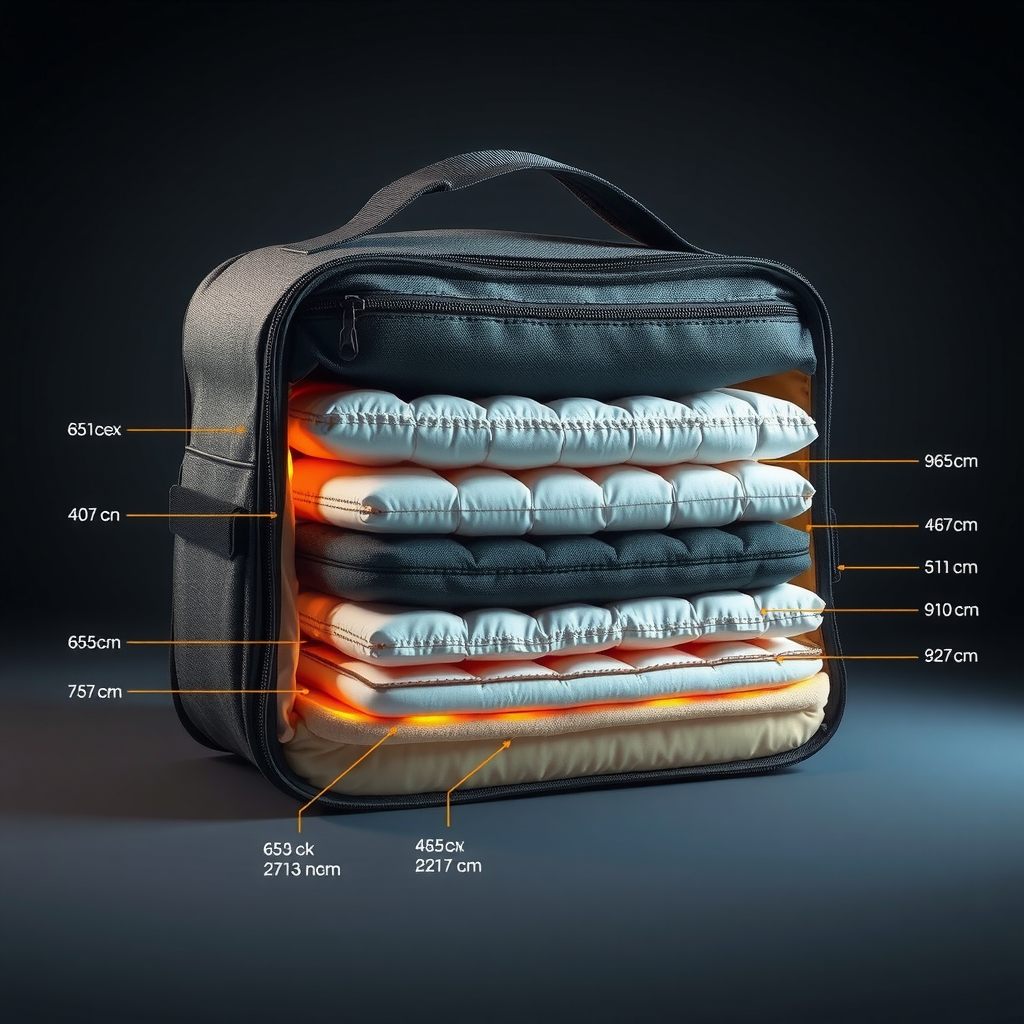

The Thermal Delivery Bag System

At the heart of our delivery system is our custom-designed thermal bag, which we affectionately call the "Hot Box Pro." Unlike standard insulated bags, ours features five distinct layers, each serving a specific purpose in the heat retention chain.

Layer One: Reflective Aluminum Interior

The innermost layer is a food-grade aluminum lining that reflects radiant heat back toward the pizza. This mirror-like surface prevents infrared heat from escaping, effectively creating a heat-reflective chamber. The aluminum is also antimicrobial and easy to clean, ensuring food safety standards are maintained.

Layer Two: Aerogel Insulation

The second layer incorporates aerogel—the same material NASA uses in spacesuits. With a thermal conductivity of just 0.013 W/mK, aerogel is one of the most effective insulators available. This 6mm layer provides the equivalent insulation of 50mm of traditional foam, allowing us to keep the bag relatively compact while maximizing thermal performance.

Layer Three: Closed-Cell Foam Barrier

A 12mm layer of closed-cell polyethylene foam provides additional insulation while also serving as a moisture barrier. This prevents condensation from forming inside the bag, which could compromise both insulation effectiveness and pizza quality. The closed-cell structure means no air or moisture can penetrate, maintaining consistent thermal performance regardless of humidity levels.

Layer Four: Thermal Break Mesh

Between the insulation and outer shell, we've incorporated a specialized mesh that creates an air gap. This thermal break prevents cold from the exterior shell from conducting inward, essentially creating a buffer zone that further slows heat loss.

Layer Five: Weather-Resistant Exterior

The outer shell is constructed from heavy-duty 1680D ballistic nylon—the same material used in high-end luggage. This provides exceptional durability while remaining flexible in extreme cold. The exterior is also treated with a DWR (Durable Water Repellent) coating to shed snow and ice, and features reinforced corners and stress points to withstand the rigors of daily delivery operations.

Vehicle Integration and Route Optimization

Even the best thermal bag can't overcome poor logistics. That's why we've developed a comprehensive vehicle integration system that works in tandem with our thermal bags to maintain optimal pizza temperature from kitchen to customer.

Each of our delivery vehicles is equipped with a custom-built heated cargo area. Unlike simple space heaters, our system uses low-wattage heating elements integrated into insulated cargo shelves, maintaining a consistent 35°C ambient temperature—warm enough to support the thermal bags without overheating the pizzas.

But hardware is only half the equation. Our proprietary routing algorithm, which we call "ThermalRoute," takes into account not just distance and traffic, but also factors like wind chill, precipitation, and even the thermal mass of different pizza types. A thick-crust meat lovers pizza retains heat differently than a thin-crust margherita, and our system accounts for these variables when planning delivery sequences.

The system also dynamically adjusts routes based on real-time conditions. If a sudden temperature drop is detected, or if traffic conditions change, ThermalRoute can instantly recalculate to prioritize orders that are most at risk of cooling below our quality threshold. During extreme weather events, the system may even recommend delaying certain orders by a few minutes to allow for batch delivery, reducing overall exposure time while maintaining our quality standards.

Our drivers are equipped with smartphone apps that provide turn-by-turn navigation optimized for thermal retention, along with real-time alerts if any order is at risk of falling below temperature thresholds. The app also tracks the temperature history of each delivery, allowing us to continuously refine our algorithms and identify areas for improvement.

The Pre-Delivery Process: Timing is Everything

The journey to a hot pizza actually begins before the pizza even enters the oven. Our kitchen operations are synchronized with our delivery logistics to ensure optimal timing at every stage.

"We don't just make pizzas and then figure out how to deliver them. Every pizza is timed to coincide with driver availability and optimal route windows. It's a carefully choreographed dance between kitchen and logistics."

— Marco Benedetti, Operations Director

When an order is placed, our system immediately calculates the optimal bake time based on current delivery capacity and route conditions. If weather is particularly severe, we may adjust oven temperatures slightly higher (within our quality parameters) to give pizzas additional thermal mass for the journey ahead.

Once a pizza exits the oven, it's immediately transferred to a pre-heated pizza box. Yes, we actually pre-heat our boxes. Each box spends 30 seconds in a warming cabinet set to 65°C before the pizza is placed inside. This eliminates the initial temperature shock that occurs when hot pizza meets a cold box, preserving precious degrees that would otherwise be lost in the first critical minutes.

The boxed pizza then goes into the thermal bag within 15 seconds—we've timed it. Our kitchen staff are trained in efficient thermal transfer techniques, minimizing air exposure at every step. The thermal bag is sealed using a magnetic closure system that's faster than zippers or velcro, shaving off additional seconds of heat loss.

From oven to vehicle, the entire process takes less than 90 seconds. During this time, the pizza loses only 2-3°C—a negligible amount that's easily compensated for by the thermal retention during delivery.

Real-World Performance and Customer Impact

The proof, as they say, is in the pizza. Since implementing our thermal delivery system two years ago, we've collected extensive data on delivery temperatures and customer satisfaction. The results speak for themselves.

of pizzas arrive above 140°C

reduction in heat loss vs. standard delivery

customer satisfaction with pizza temperature

We've conducted blind taste tests comparing pizzas delivered with our system versus standard methods. Participants consistently rated our deliveries higher in terms of cheese meltiness, crust texture, and overall temperature satisfaction. Even after 35-minute deliveries in -25°C weather, our pizzas scored within 5% of fresh-from-oven ratings—a remarkable achievement that we're incredibly proud of.

Customer feedback has been overwhelmingly positive. Comments like "I can't believe how hot this pizza is!" and "It's like it just came out of the oven!" are now commonplace in our reviews. During the brutal winter of 2024, when temperatures regularly dropped below -30°C, we actually saw an increase in delivery orders—customers trusted us to deliver quality even in the worst conditions.

The system has also had unexpected benefits for our drivers. The heated cargo area means they're not constantly opening and closing doors to check on orders, reducing their exposure to extreme cold. Driver satisfaction has increased, and we've seen lower turnover rates during winter months—a traditionally challenging time for delivery services.

Continuous Innovation: What's Next

While we're proud of what we've achieved, we're not resting on our laurels. Our research and development team is constantly exploring new technologies and methods to further improve our thermal delivery system.

Phase Change Materials

We're currently testing phase change materials (PCMs) that can store and release heat at specific temperatures. These materials absorb heat when the pizza is first placed in the bag, then slowly release it during delivery, maintaining a more consistent temperature profile. Early tests show promise for extending our effective delivery range by an additional 10-15 minutes without temperature loss.

Smart Thermal Monitoring

We're developing IoT-enabled thermal sensors that will be embedded in our delivery bags, providing real-time temperature data for each individual pizza. This will allow us to track thermal performance with unprecedented precision and alert drivers immediately if any order is at risk. Customers will also be able to see the current temperature of their pizza through our app—complete transparency in our delivery process.

Electric Vehicle Integration

As we transition our fleet to electric vehicles, we're designing custom battery-powered heating systems that are more efficient and environmentally friendly than our current setup. The instant torque of electric motors also allows for faster acceleration and more responsive routing, potentially reducing delivery times by 10-15% while maintaining our thermal standards.

Predictive Weather Integration

We're partnering with Environment Canada to integrate hyperlocal weather forecasting into our routing system. This will allow us to anticipate temperature changes, wind patterns, and precipitation with greater accuracy, adjusting our operations proactively rather than reactively. Machine learning algorithms will analyze historical weather data alongside delivery performance to continuously optimize our thermal strategies.

The Salvatore Promise

At Salvatore, we believe that delivery shouldn't be a compromise. When you order from us, you should receive the same quality pizza that you'd get sitting in our restaurant—hot, fresh, and perfect. Our thermal delivery system isn't just about technology; it's about respect for our craft and commitment to our customers.

Every pizza we make is a product of generations of Italian tradition, premium ingredients, and skilled craftsmanship. It would be a disservice to that heritage to let our pizzas arrive anything less than perfect. That's why we've invested so heavily in our delivery infrastructure—because we believe every customer deserves the best, regardless of the weather outside.

Experience the difference for yourself

Order from Salvatore today and taste what true thermal delivery excellence means. Even in the coldest Canadian winter, we guarantee your pizza will arrive hot enough to burn your tongue—in the best possible way.

The next time you bite into a Salvatore pizza delivered to your door on a frigid winter evening, know that you're experiencing the result of years of research, innovation, and dedication. From our thermal engineers to our drivers, from our kitchen staff to our logistics team, everyone at Salvatore is committed to one goal: delivering perfection, one hot pizza at a time.

Because in Canada, where winter is a way of life, we don't just deliver pizza. We deliver warmth, comfort, and the assurance that quality never has to be compromised—no matter how cold it gets outside.

Share this article

Category

Innovation & Technology